Function errors/warnings/messages

Perform cross-section calculations and NEN-checks

Function ready condition: - if input data table SECTION is tested.

Function error condition: 1 error condition, 3 warning conditions, 5 messages

Data missing, recalculate from DF5.

Internal data calculated in design function 5 can not be found. Please set back design function 5 and recalculate from there.

(This error can occur after updating a project from a previous version of the program. If only design function 6 is recalculated after the update, not all required data might be present. )

Ovalisation is 'value' % of diameter

The ovalisation of an element exceeds 10 % of the diameter.

(An ovalisation exceeding 10% is considered to be very large.)

Calculated stress > allowable stress

One of the calculated normalised stresses in table NENSMAX exceeds 1.

Axial buckling strain > critical one

The calculated maximum axial buckling strain is greater than the critical buckling strain.

Axial torsion strain > critical one

The calculated maximum axial torsion strain is greater than the critical torsion strain.

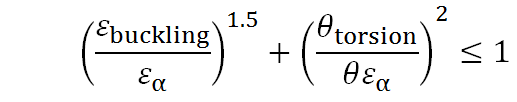

Did not pass axial buckling check

Did not pass axial buckling check from NEN:

Weak element(s) not calculated

Only WEAK elements have been specified in (a row of) table SECTION.

No elements calculated

Only WEAK elements have been specified in table SECTION.

All elements already calculated

All pipeline cross-sections specified in table SECTION are already calculated including the detailed stresses of the last specified element in table SECTION.

Topload = 0.

The TOPLOAD indicator in table SECTION is YES and (the TOPLOAD-value =0. and the Loading Redistribution option is OFF or no table TOPLOAD exists).

•in output table CSLOAD the relevant TOPLOAD-value will become indicated .0 or UNDEFINED if no table TOPLOAD exists.

(This message is given to indicate that the TOPLOAD specified is zero over (parts of) the pipeline. this may be the real situation, but it is also possible that input of the TOPLOAD table has been omitted erroneously.)

Adjustment of SIX stopped after 100 iterations

In NEN3650 calculations the overall maximum stress intensification factor SIX calculated in DF5 must fit the SXUB1 and SXUBH components calculated in design function 6.2. Bringing those values into agreement was stopped after 100 iterations.

(The SIX used in design function 6.2 will differ from the value reported in design function 5, table “Bend stiffness reduction & stress intensification” [BENDFAC].)

H6304, last changed: 24/04/2019

See also: